|

OPERATED BY: Toros Gubre ve Kimya Endustrisi A.S. - CEYHAN

ADDRESS: Toros Gubre. Sarimazi Ceyhan P.K. 83, Turkey

TELEPHONE: (326) 634 22 22 - 613 50 01 / 4 lines

FAX: (326) 634 23 23

LOCATION: 36° 55' 06" N, 35° 58' 54" E

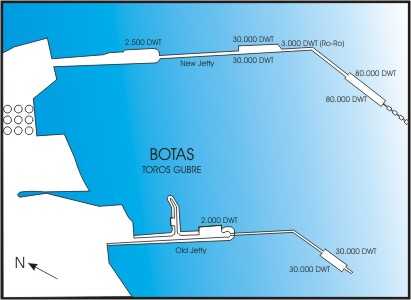

PORT DESCRIPTIONS: Toros Gubre is in the Botas (Ceyhan) port limits. Toros Marine Terminal, a multipurpose

deep water marine terminal located at Ceyhan in Iskenderun Bay on the eastern Mediterranean, is internationally

competitive in efficiency and capacity. As Turkey's largest dry bulk port, the Marine Terminal.

gives port, storage and bagging services for: coal , petroleum coke, clinker, pumice stone, fertilizers, grains

and feedgrains , edible oils, petroleum products.

ANCHORAGES: See "Botas Ceyhan Terminal."

RESTRICTIONS: Mooring is carried out during daylight only, Unmooring is carried out around the clock.

PILOTAGE: Compulsory. The pilot will meet vessels 1,5 miles south of the end of the jetties. Provided by

Toros Pilot on VHF channel 16, 13, 12.

TOWAGE: There are 4 tugs Provided by Botas terminal.

DENSITY: salt water 1027.

FRESH WATER: available at jetty.

BUNKER: not available.

AIRPORT: At Adana distance 82 km from the port.

BALLAST: There is one ballast tank with a capacity of 5,000 cu.m.

Click for enlarge picture

WORKING HOURS: operates 24 hours a day year round,

First shift: 07.00-15.00. Second Shift: 15.00-23.00. Third Shift: 23.00-07.00.

CARGO HANDLING EQUIPMENTS: with deep-sea berthing facilities, the Terminal is supported by high capacity

loading/unloading equipment able to handle up to 17,000 mtpd at each of its two main berths.

Vessels are accommodated depending on their size and cargo type in eight berths alongside two jetties. Two of these

have a 14.50 m. safe draft, four have a 11-12 m. draft and two are reserved for coasters with a 5 m. draft. A totally

covered conveyor system composed of four lines links the jetty operations with a 60,000 mt flat grain silo and

two 50,000 mt bulk warehouses. Total bagging capacity of 14,000 mtpd allows simultaneous bagging and loading to

vessels.

CONVEYOR SYSTEM: Four lines conveyor system (two incoming and two outgoing lines) connects the main

and central platforms to the warehouses and bagging/truck loading units. One incoming line system

connects the platform no.1 to the fertilizer warehouses.

Outgoing Lines: Two lines both with capacity of 400 mt/hr for bulk or 2.500 bags/hr for bagged cargo.

STORAGE FACILITIES: Open storage:400.000 m2 including 75,000 m2 with concrete ground. Covered storage flat

grain silo with four chambers 60.000 tons, bulk warehouse 2x50.000 tons and 41 tanks with a total capacity of 189.000

m3.

LOADING/DISCHARGING CAPACITIES: *Dray bulk cargo loading/unloading capacity. *14.000 tpd. Bagged cargo facilities

14.000 tpd. Discharge Equipment Two jetty grab cranes 400 tph each; Pneumatic unloader 300 tph; Chain unloader

300 tph; Two Ship loaders 400 tph each for bulk cargo 2,500 bags/hour;Central platform Jetty grab crane 300 tph.

Chemicals products 6-14in. hoses connect.

OTHER INFORMATION: Stevedoring services are offered by Toros Gubre.

BERTHING: There are 3 loading berths available on the old jetty, and 6 loading berths available on the new

jetty.

BERTH LOA DRAFT MAX. DWT CARGO CRANES

No.1-2 Platform (tankers only) 120 m 11 m 40.000 Liquid cargo 1x175T,1x125T

No.3 Platform 101 m 5 m 2.500 Bulk-bagged Mobile Cranes

No.4 - 5 Main Platform 187 m 14-16m 110.000- Bulk-bagged 2x400T

No.6- 7 Central Platform 155 m 12 m 35.000 Liquid cargo 1x300T

No.8 Platform 101 m 5 m 2.500 Bulk-bagged Mobile Cranes

Ro-Ro ramp 12 m 12 m 8.000

|